How To Reduce Silica In Bauxite

(PDF) Reduction of Reactive Silica from Bauxite

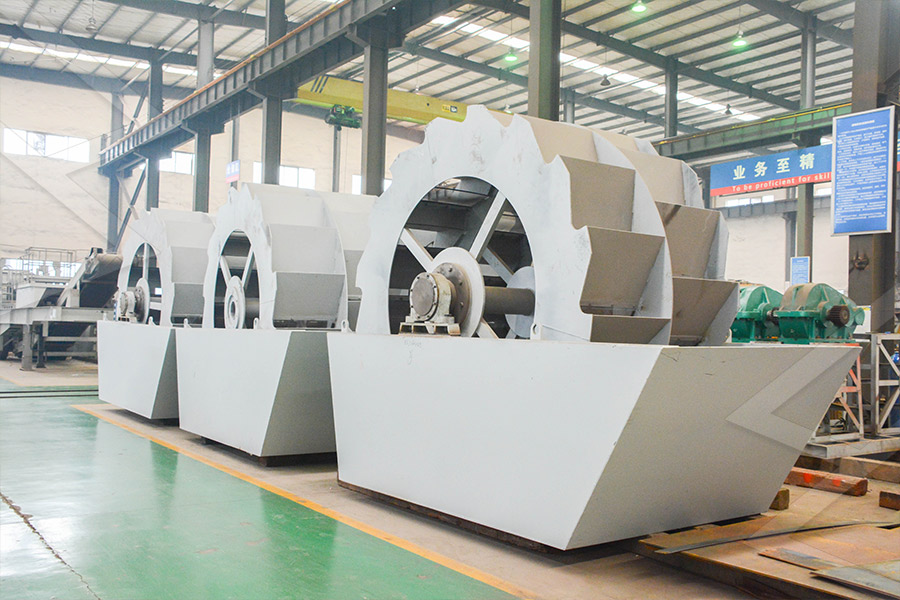

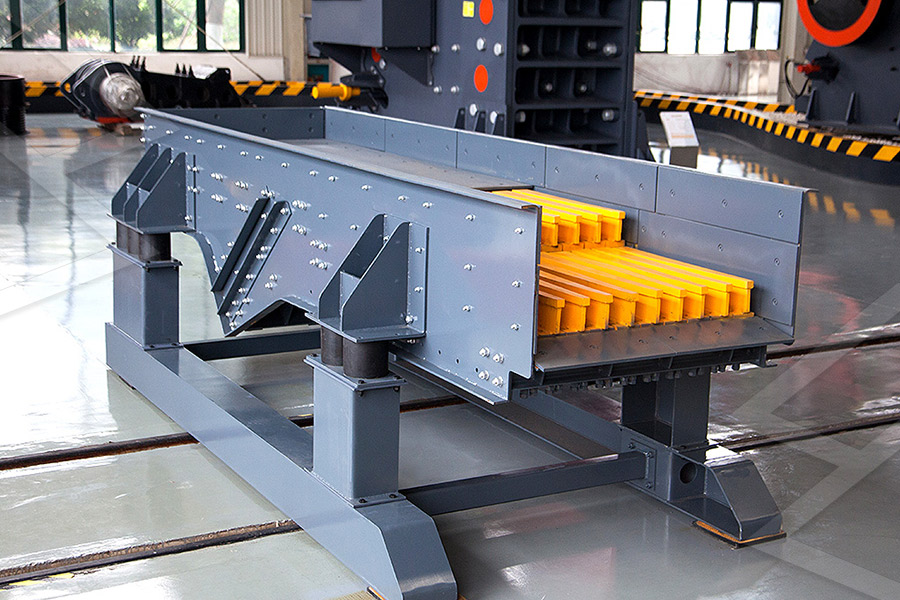

2012年11月18日 With this knowledge, a methodology was developed in order to promote the reduction of reactive silica Therefore, particle surface 2009年8月1日 Screening and washing is effective in reducing silica in the bauxite feed material if the silica is preferentially concentrated in the smaller particle size fractions or fines Bauxite is The processing of high silica bauxites ScienceDirect2020年12月20日 Efforts to remove reactive silica from bauxite ore prior to shipment have largely focused on gravitational methods such as washing, screening and the use of hydrocyclones BX03 Reducing Reactive Silica Content in Washed 2021年7月2日 Any beneficiation process, which can effectively reduce the silica content of bauxite (mainly in reactive form such as kaolinite) is given the first priority in the metallurgical Bauxite Beneficiation: An Approach to Value Addition in the present invention provides a process for removing silica from bauxite including the steps of mixing bauxite with a caustic liquor to form a mixture and to dissolve at least a substantialEPA1 Removal of silica from bauxite Google 2023年12月23日 Reactive silica (RS) reacts with sodium hydroxide (NaOH) in the Bayer process, consuming it in the precipitation of the desilication product (DSP) This increases Reactive Silica Reduction on Bauxite by Flotation

Treatment and Beneficiation of High Silica Bauxite

2025年2月15日 Reduce silica content in the bauxite by between 40 – 50% of current levels to a target bandwidth of 6 – 8% Optimise the silica content in the bauxite feed to reduce caustic 2017年1月20日 This paper reports a study that implements reverse flotation method to separate silica from West Kalimantan bauxite ores The study is aimed to find the good process Implementation of reverse flotation method to reduce Physical beneficiation techniques are employed to reduce the reactive silica content of bauxite Based on several investigations it has been made possible to remove ~30% of silica with 92% Beneficiation of High Silica Bauxite Ores of India an 2020年9月9日 some residual reactive silica in the bauxite feeding digestion which tends to dissolve, raising silica levels in the digested slurry In addition to this the higher temperatures and caustic to reduce the silica concentration [Rodda and Shaw, 1997] Ultrasonic irradiation treatment has also been used to remove ,MANAGEMENT AND CONTROL OF SILICA IN THE BAYER 2023年4月3日 Bauxite is a sedimentary rock mineral that is the primary source of aluminum It is formed through the weathering of aluminumrich rocks in tropical and subtropical regions The name bauxite is derived from the French Bauxite Properties, Formation, Uses » 2021年7月1日 The main objective of bauxite beneficiation is to lower the concentration of reactive silica, in the form of kaolinitic clay, and also to increase the alumina contentBauxite Beneficiation: An Approach to Value

.jpg)

Beneficiation of bauxite

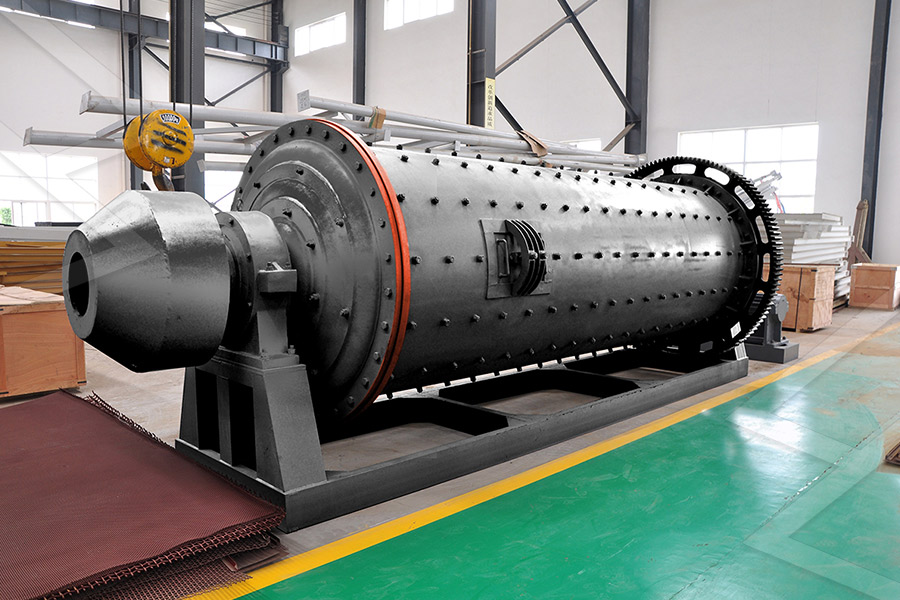

2011年8月11日 The silica present in the bauxite tends to be concentrated in the finer grained fractions, and this characteristic makes bauxite amenable to beneficiation by screening techniques Pearson' has reported that in a bauxite of average composition of 158% silica, the minus 100 mesh fraction analysed a silica content as high as 1030%A process for removing silica from bauxite is disclosed The method includes the step of mixing bauxite with a caustic liquor to form a mixture and to dissolve and stabilise at least a substantial part of the reactive silica from the bauxite The caustic liquor is selected to have a high caustic concentration and a high alumina contentEPA1 Removal of silica from bauxite Google 2017年1月20日 This paper reports a study that implements reverse flotation method to separate silica from West Kalimantan bauxite ores The study is aimed to find the good process condition to obtain lowsilica bauxite as the feed for the Bayer process The experiments were carried out in a 1 L of flotation cell tankImplementation of reverse flotation method to reduce 2009年8月1日 When the mixture of the highsilica bauxite and Na2CO3 with mole ratio of Na2O/(Al2O3 + SiO2) of 1 was sintered at 950 °C for 30 min, diaspore and kaolinite were primarily converted into Na1 The Processing of High Silica Bauxites ResearchGate2023年12月23日 In all tested conditions the alumina/silica relation in flotation concentrate was greater than 10 The highest reactive silica reduction was under 400 g/t of collector dosage with available alumina recovery of 735 %, eliminating 47 % of re silica content The elimination of 47% of reactive silica content on bauxite is a huge benefit to reduce theReactive Silica Reduction on Bauxite by FlotationThe first fraction corresponded to crystallized bauxite (CB), commercially exploited by industry, whereas the other one corresponded to crystallized amorphous bauxite (CAB) a marginal bauxite unprofitable to the Bayer process due to its high contents of reactive silica, with particle size lower than 100 mm Samples were submitted to a study (PDF) Reduction of Reactive Silica from Bauxite Academia

Characterization Study of some Bauxite Deposits in Northern

2024年4月2日 Silica, when in the form of Kln, poses a problem in the Bayer process as it reacts with NaOH during bauxite digestion, forming insoluble compounds that reduce the profitability of the process In contrast, when silica is in the form of quartz, it exhibits inert behavior and does not significantly impact the consumption of NaOH, referred to as 2023年1月4日 most commercially important impurity in bauxite as generally the more silica in the bauxite, the higher the amount of caustic soda consumed in the refining process and the higher the loss of alumina to the red mud tailings in the desilication product (DSP) The two main sources of silica in bauxite are kaolinite and quartz Kaolinite • Kaolin Bauxite alsglobal2023年12月22日 The most effective way to reduce your exposure to silica dust is by following the Hierarchy of Controls, which organises control measures from the highest level of effectiveness (Elimination) to the lowest level (PPE) Following this hierarchy can reduce your risk of developing silicosis or otherSilica dust in the mining and quarrying industry2019年2月16日 Aluminum industries use bauxite as the major raw material Bauxite containing less than 50% Al 2 O 3 is called lowgrade bauxite ore, which is generally used for the production of aluminum appliances such as abrasives, ceramics, and refractories The presence of impurities, including silica, iron oxides, and calcium contribute to the bauxite being classified Advances in Beneficiation of LowGrade Bauxite SpringerLinkHigh Silica Bauxite Processing High silica bauxites detailed process review, process selection and innovation 1 Reduce the input of reactive silica to the process This could take the form ofHigh silica bauxites detailed process review, process 2017年9月1日 • 5% of RSilica is equivalent to 67% of Total Silica, which may go up to to 78% during mining as both top bottom profile of bauxite are highly undulating in nature So every 1% excess of RSilica results more consumption of caustic soda and creates digestion problem • Hence, threshold value of Silica in bauxite ore should be based on THRESHOLD VALUE OF BAUXITE IBM

.jpg)

Beneficiation of bauxite ores ScienceDirect

2023年1月1日 Various attempts have been made to characterize and beneficiate bauxite ores across the globe Studies conducted at Hindalco with typical bauxite ore from Central Indian deposits have revelated that such ores are amenable to simple beneficiation process to reduce the reactive silica content to some extent2023年12月23日 reduce fine particles bypass from 14 % to 6 % [8] Hydro Paragominas processes lateritic Amazon bauxite To remove kaolinite, the beneficiation plant has two cyclone stages in two different circuits (fines and superfines) Seeking to reduce the content of reactive silica in bauxite a pilot plant was installed in the superfines circuit, withPilot Tests with Tertiary Cyclone for Reactive Silica 2022年3月1日 Bayer process is the primary method to extract alumina from bauxite in the world [21] In many modern alumina plants, a predestination stage, during which the slurry of bauxite and sodium aluminate solution is kept at ~95 °C for several hours, is conducted to convert the silica into solid desilication products, as shown in EqsSeparation of alumina and silica from metakaolinite by 2022年1月23日 Batch predesilication test results of a high reactive silica boehmitic bauxite from Nyírád (Hungary) ar e shown on Figures 449 [8] The bauxite contained 488 % Al 2 O 3 , of which 37 % was (PDF) Chemical Processing of Bauxite: Alumina and Silica 2023年12月19日 Bauxite is generally hard, heterogeneous in appearance and can be nodular, layered or massive It has varying composition but is relatively rich in aluminium oxides along with iron and silica oxides with minor quantities of other minerals resistant to weathering, such as anatase (titanium dioxide)Bauxite Geoscience Australia2023年1月1日 Various attempts have been made to characterize and beneficiate bauxite ores across the globe Studies conducted at Hindalco with typical bauxite ore from Central Indian deposits have revelated that such ores are amenable to simple beneficiation process to reduce the reactive silica content to some extentBeneficiation of bauxite ores ScienceDirect

.jpg)

Characterization and flotation of lowgrade boehmitic bauxite

2021年1月15日 Bauxite is the main raw material in primary aluminum production and its reactive silica content and mass ratio of Al 2 O 3 to SiO 2 (A/S) has a critical role in the economic viability of Bayer process As a major source of the reactive silica, clay impurities should be removed from the ore as much as possible by a beneficiation method such as froth flotation before the Bayer high silica and alumina have adverse eff ects on the reducibility of the iron ore and sinter plant productivity The specifications for iron grade and quantities of impurities in the commercial iron ores/ iron concentrates require above 60% Fe, below 5% (SiO2+Al2O3), and less than 01% P [3] Thus, impurity removal from iron oreRemoval of Silicon, Aluminum and Phosphorus 2024年2月14日 associated with screening, promoted a decrease of approximately 75% of reactive silica in the fraction above 37 µm After this treatment, the marginal bauxite studied showed a proportion ofReduction of Reactive Silica from Bauxite ResearchGate2021年1月25日 goethite, hematite and small amounts of titanium, silica and other minerals and other impurities in minor or trace amounts Bauxite usually contains the clay mineral kaolinite and has a density ranging from 2 600 to 3 500 kg/m3 Bauxite colour varies from whitish to pink to reddish brown depending on the iron content in the bauxite[1]An Overview of Bauxite Residue Utilisation ICSOBAcan be used to reduce caustic soda consumption, especially at higher temperatures Lime increases the desilication efficiency of the bauxite digesting In addition to reduce silica content in sodium aluminate solution, lime can also minimize impurities like carbonate, silica, and phosphor of this solution [1] Sodium aluminate solution is most Implementation of Mathematical Equation for 2023年11月1日 Bauxite residue (BR) is generated as a byproduct of the Bayer process Approximately 12 tons of BR is generated per ton of alumina production but the quantity of bauxite residue depends upon on the quality of the processed bauxite ore and the processing parameter (Primary Aluminium Production)The annual generation of BR in 2019 alone was Alumina recovery from bauxite residue: A concise review

.jpg)

How to Separate Aluminum and Iron from Bauxite with

2024年1月25日 It mainly uses reducing gas (or coal) as a reducing agent to reduce the iron in bauxite into strong magnetite, and then uses magnetic separation to separate the magnet and bauxite The process is to crush the raw ore to 5mm, add 25% coke amount, and conduct magnetization roasting at a roasting temperature of 780°C and a roasting time of 45 The removal of silica (a problem with high silica bauxite) (b) Chinese domestic bauxite production peaked in 2018 and is now declining on depleting reserves, lower grades, and environmental constraints China's declining bauxite output continues to accelerate bauxite imports It is estimate that in 2020–21, only 70 million tons of how to reduce silica in bauxite grainedefantaisie2020年9月9日 some residual reactive silica in the bauxite feeding digestion which tends to dissolve, raising silica levels in the digested slurry In addition to this the higher temperatures and caustic to reduce the silica concentration [Rodda and Shaw, 1997] Ultrasonic irradiation treatment has also been used to remove ,MANAGEMENT AND CONTROL OF SILICA IN THE BAYER 2023年4月3日 Bauxite is a sedimentary rock mineral that is the primary source of aluminum It is formed through the weathering of aluminumrich rocks in tropical and subtropical regions The name bauxite is derived from the French Bauxite Properties, Formation, Uses » 2021年7月1日 The main objective of bauxite beneficiation is to lower the concentration of reactive silica, in the form of kaolinitic clay, and also to increase the alumina contentBauxite Beneficiation: An Approach to Value 2011年8月11日 The silica present in the bauxite tends to be concentrated in the finer grained fractions, and this characteristic makes bauxite amenable to beneficiation by screening techniques Pearson' has reported that in a bauxite of average composition of 158% silica, the minus 100 mesh fraction analysed a silica content as high as 1030%Beneficiation of bauxite

.jpg)

EPA1 Removal of silica from bauxite Google

A process for removing silica from bauxite is disclosed The method includes the step of mixing bauxite with a caustic liquor to form a mixture and to dissolve and stabilise at least a substantial part of the reactive silica from the bauxite The caustic liquor is selected to have a high caustic concentration and a high alumina content2017年1月20日 This paper reports a study that implements reverse flotation method to separate silica from West Kalimantan bauxite ores The study is aimed to find the good process condition to obtain lowsilica bauxite as the feed for the Bayer process The experiments were carried out in a 1 L of flotation cell tankImplementation of reverse flotation method to reduce 2009年8月1日 When the mixture of the highsilica bauxite and Na2CO3 with mole ratio of Na2O/(Al2O3 + SiO2) of 1 was sintered at 950 °C for 30 min, diaspore and kaolinite were primarily converted into Na1 The Processing of High Silica Bauxites ResearchGate2023年12月23日 In all tested conditions the alumina/silica relation in flotation concentrate was greater than 10 The highest reactive silica reduction was under 400 g/t of collector dosage with available alumina recovery of 735 %, eliminating 47 % of re silica content The elimination of 47% of reactive silica content on bauxite is a huge benefit to reduce theReactive Silica Reduction on Bauxite by FlotationThe first fraction corresponded to crystallized bauxite (CB), commercially exploited by industry, whereas the other one corresponded to crystallized amorphous bauxite (CAB) a marginal bauxite unprofitable to the Bayer process due to its high contents of reactive silica, with particle size lower than 100 mm Samples were submitted to a study (PDF) Reduction of Reactive Silica from Bauxite Academia2024年4月2日 Silica, when in the form of Kln, poses a problem in the Bayer process as it reacts with NaOH during bauxite digestion, forming insoluble compounds that reduce the profitability of the process In contrast, when silica is in the form of quartz, it exhibits inert behavior and does not significantly impact the consumption of NaOH, referred to as Characterization Study of some Bauxite Deposits in Northern